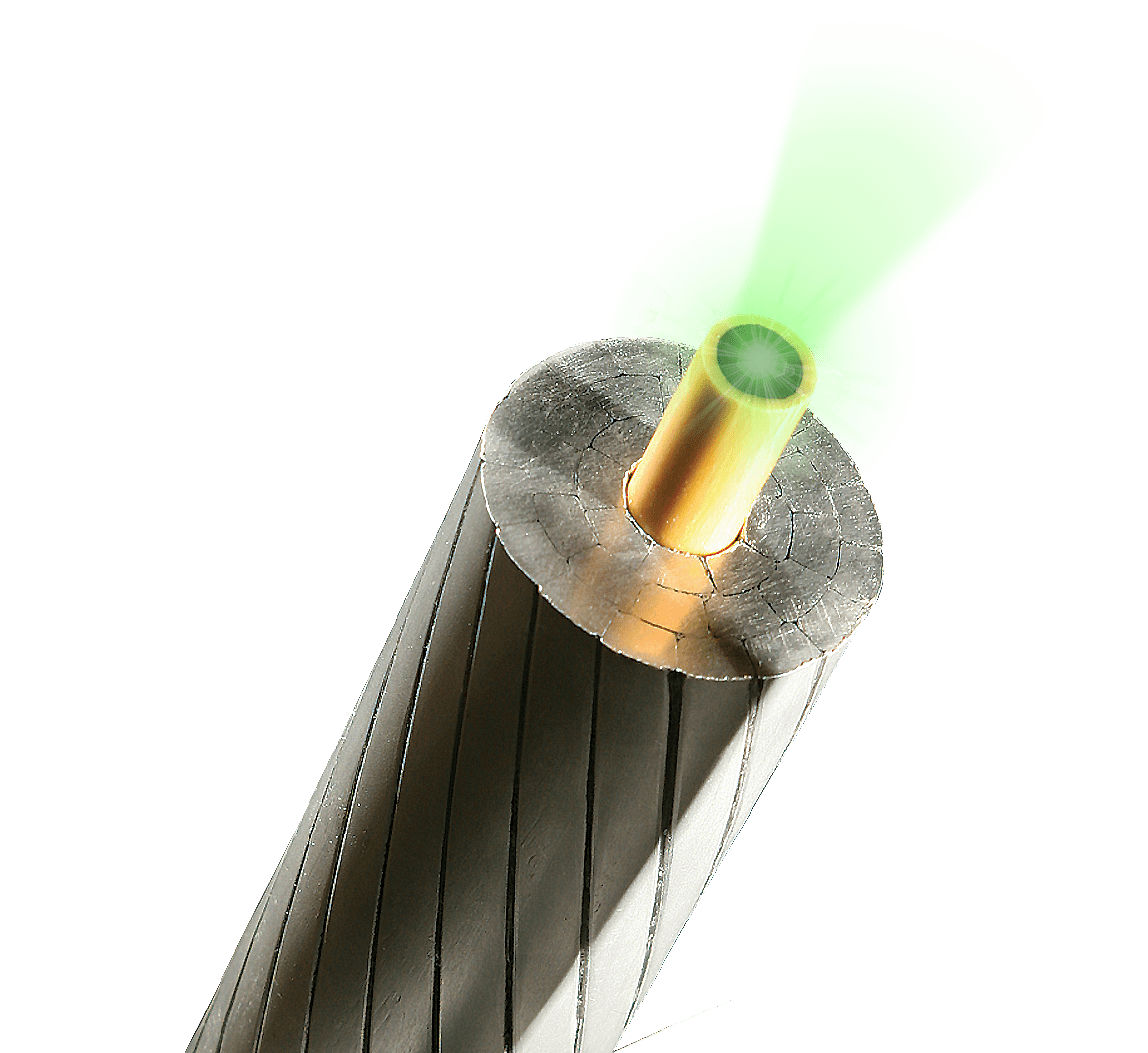

ACCC InfoCore™ System

ACCC Conductor using Special Fibers in the Core

CTC Global developed the ACCC InfoCore™ System to provide an innovative method of confirming a successful installation by crews in the field. The ACCC InfoCore™ System utilizes special fibers embedded in the core of the ACCC® Conductor, which allows for inspection in a simple and effective process. By using a proprietary

infrared light system, special fibers in the core, and a robust data-capture and recording methodology, the InfoCore System can confirm the integrity of the conductor in minutes.

The ACCC InfoCore™ System reduces real-world conductor installation risk experienced by utilities, contractors and lineman across the globe.

The system is capable of confirming very long continuous spans and is currently being utilized globally.

How it Works

The process begins by accessing the conductor at each end, prepping the core ends using tools provided in the ACCC InfoCore™ Confirmation Kit.

- Transmitter is attached to one end of the ACCC® Conductor.

- Receiver is attached to the other end.

- Controller receives, reviews and records the results.

- Core prep generally takes less than five minutes and the receiver confirms a successful installation in seconds.

CTC Global’s ACCC InfoCore™ System makes confirming successful conductor installation safe, simple and fast. Alternate methods include CT Scan, X-ray inspection, and magnetic pulse technology but these devices are very slow and expensive.

The ACCC InfoCore™ System reduces real-world conductor installation risk experienced by utilities, contractors and lineman across the globe. These dedicated professionals know that even with the best tools, equipment and field conditions, accidents can happen. By using a proprietary infrared light system, special fibers in the core, and a robust data-capture and recording methodology, the ACCC InfoCore™ System can confirm the integrity of the conductor in minutes. While not mandatory for every installation, this capability serves to improve reliability and confidence. The system is capable of confirming very long continuous spans and is currently being utilized globally.

This System is commercially available and has been deployed to a number of sites worldwide. It is noteworthy that there is no performance difference between ACCC® Conductor and ACCC InfoCore™ Conductor. ACCC InfoCore™ Field Verification Kits are easy to use, and available through CTC Global’s Master Installers network.

Key Features

There is no performance difference between ACCC® Conductor and ACCC InfoCore™ Conductor.

Reduces conductor installation risk experienced by utilities, contractors and lineman across the globe.

Makes confirming successful conductor installation safe, simple and fast.

Other Products

QUASAR

Three Phase Industrial Grade Protective Relay Test Set with cloud technology

Powerful and flexible

- 4 x 300V + 3 x 60A outputs, switchable to 7 current outputs

- 6 binary inputs + 4 binary outputs

- External DC current and voltage measurement

- 6 low-level outputs to test sensors, meters etc, and to upgrade with more channels

- Integral Wi-Fi, Ethernet LAN, dedicated IEC-61850 port and Expansion port

- Field serviceable

Rugged and portable

- 19.5 kg (43 lb)

- Integral ABS casing with wheels and extensible handle. No separate travel case needed.

Familiar User Interface

- Conduct quick or pre-configured tests directly from your tablet or smartphone

- Connect to your Windows computer for automated, exhaustive testing

VLF SIN 62

VLF sine wave test system for medium voltage cables with integrated Tan Delta

- Performs cable withstand testing, cable diagnosis, and sheath fault pinpointing

- Smallest and lightest unit on the market in its class

- Unique user-experience, thanks to a large, colour touch screen

- Automatic result interpretation as per latest IEEE 400.2 standard

- High safety, thanks to its analogue residual voltage indicator

TDM 45

High power test and diagnosis combination for MV cables (Tan Delta, VLF and PD)

- Cable testing, cable diagnosis, and sheath testing in one device

- Enables standard compliant high power VLF testing at 0.1 Hz (5 µF at 40 kV RMS)

- Internal tan delta measurement with automatic result interpretation

- Partial discharge diagnosis using VLF sine wave, damped AC or 50/60 Hz slope technology voltages