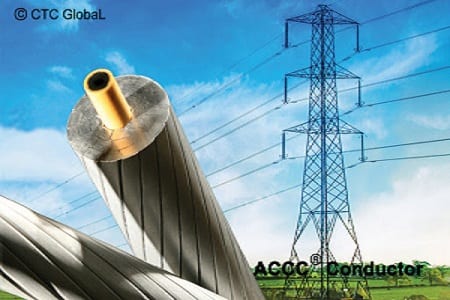

ACCC Conductor

High Performance Conductors for a Low Carbon World

The CTC Global ACCC® Conductor utilizes a hybrid carbon and glass fiber core embedded in a high-performance thermoset epoxy matrix. The central carbon fiber core consists of tens of thousands of high-strength, high-modulus unidirectional carbon fibers that are surrounded by a protective layer of glass fibers. The outer glass fibers improve toughness and flexibility while also providing a galvanic barrier to prevent corrosion with the conductive aluminum strands.

The ACCC Conductor hybrid core is not only twice as strong as steel, it is also 70% lighter.

The lighter weight allows the CTC Global ACCC Conductor – of any size – to utilize ~28% more aluminum without a weight or diameter penalty.

Commercially deployed in 2005, the ACCC® Conductor offers an abundance of advantages that help the electric power industry meets a growing list of challenges. Derived from advanced aerospace technology.

The CTC Global ACCC® Conductor utilizes a hybrid carbon and glass fiber core embedded in a high-performance thermoset epoxy matrix. The central carbon fiber core consists of tens of thousands of high-strength, high-modulus unidirectional carbon fibers that are surrounded by a protective layer of glass fibers. The outer glass fibers improve toughness and flexibility while also providing a galvanic barrier to prevent corrosion with the conductive aluminum strands.

The ACCC Conductor hybrid core is not only twice as strong as steel, it is also 70% lighter. The lighter weight allows the CTC Global ACCC Conductor – of any size – to utilize ~28% more aluminum without a weight or diameter penalty. The compact trapezoidal strands and smooth surface composite core work in unison to dissipate wind-induced vibration. While the aluminum strands are fully annealed, offering the highest degree of conductivity for any aluminum available today, the composite core offers a coefficient of thermal expansion about ten times less than steel.

The low coefficient of thermal expansion mitigates conductor sag under heavy electrical load conditions. While the composite core is fully elastic and will not plastically deform or yield like conventional conductor steel core strands, the overall modulus of the CTC Global ACCC Conductor core is lower than that of steel. The lower modulus allows the ACCC Conductor to stretch degree during extreme ice and wind loading events. However, when the event subsides, the composite core fully returns to its pre-stressed condition allowing the aluminum strands to subsequently relax. This type of event further improves the ACCC Conductor’s self-damping characteristics and reduces the conductor’s thermal knee-point to further reduce conductor sag under heavy electrical load conditions.

In some cases pre-tensioning can be performed during installation to achieve these added benefits. When heavy ice and wind load conditions are anticipated, CTC Global and its worldwide stranding partners also offer a higher-modulus version of the composite core known as ULS. ACCC ULS Conductors are also frequently used on long spans.

Key Features

Twice the electrical capacity

Twice the electrical capacity of conventional conductors

The ability to mitigate thermal sag

The ability to mitigate thermal sag(due to the low coefficient ofthermal expansion of its carbon fiber composite core)

Low Cost

The ability to reduce upfront capital costson new lines by increasingspans between fewer and/or shorter structures

Increase Efficiency

An increase in efficiency ranging from 25% to 40% or more

Improved Reliability

Improved reliability through the reduced risk of sag-trip outages, ability to endure cyclic load fatigue(vibration), and resistance to corrosion from industrial, agricultural, and corrosive air environments

Improved Grid Resilienceas

Improved grid resilienceas the ACCC®Conductor has survived numerous catastrophic events in thefield with little to no damage

Other Products

QUASAR

Three Phase Industrial Grade Protective Relay Test Set with cloud technology

Powerful and flexible

- 4 x 300V + 3 x 60A outputs, switchable to 7 current outputs

- 6 binary inputs + 4 binary outputs

- External DC current and voltage measurement

- 6 low-level outputs to test sensors, meters etc, and to upgrade with more channels

- Integral Wi-Fi, Ethernet LAN, dedicated IEC-61850 port and Expansion port

- Field serviceable

Rugged and portable

- 19.5 kg (43 lb)

- Integral ABS casing with wheels and extensible handle. No separate travel case needed.

Familiar User Interface

- Conduct quick or pre-configured tests directly from your tablet or smartphone

- Connect to your Windows computer for automated, exhaustive testing

VLF SIN 62

VLF sine wave test system for medium voltage cables with integrated Tan Delta

- Performs cable withstand testing, cable diagnosis, and sheath fault pinpointing

- Smallest and lightest unit on the market in its class

- Unique user-experience, thanks to a large, colour touch screen

- Automatic result interpretation as per latest IEEE 400.2 standard

- High safety, thanks to its analogue residual voltage indicator

TDM 45

High power test and diagnosis combination for MV cables (Tan Delta, VLF and PD)

- Cable testing, cable diagnosis, and sheath testing in one device

- Enables standard compliant high power VLF testing at 0.1 Hz (5 µF at 40 kV RMS)

- Internal tan delta measurement with automatic result interpretation

- Partial discharge diagnosis using VLF sine wave, damped AC or 50/60 Hz slope technology voltages